Key Takeaways

- Utilizing lightweight materials like aluminum and composites enhances fuel efficiency and payload capacity.

- Incorporating advanced safety features and ergonomic designs improves driver safety and comfort.

- Integrating modular storage systems and technology solutions boosts operational efficiency and adaptability.

Introduction

Fleet vehicle upfitting continues to advance rapidly, introducing cutting-edge methodologies that transform commercial vehicle operations. In today’s competitive landscape, fleet managers are pressed to find ways to maximize efficiency, safety, and adaptability, ensuring their vehicles are not only high-performing but also tailored to specific service needs. Companies like TCS Upfitting are redefining the boundaries of what is possible in the upfitting industry by offering innovative solutions that set new standards for reliability and customization.

Whether you manage a small business fleet or oversee hundreds of service vehicles, understanding the latest trends in upfitting empowers you to make smarter investments for your organization. Leveraging new technologies, advanced materials, and modular systems means fleets can do more with less, improving both sustainability and efficiency from day one. Partners such as Tcsupfitting.com bring a blend of expertise and adaptability to meet this new era of fleet requirements, providing comprehensive solutions for every industry sector.

Embracing Lightweight Materials

The shift from traditional steel bodies to lighter materials, including aluminum and advanced composites, is gaining momentum in the world of fleet upfitting. These materials not only reduce the total vehicle weight but also enhance fuel efficiency and boost payload capacity by hundreds of pounds. In many cases, service bodies constructed with aluminum can weigh up to 900 pounds less than their steel counterparts, giving fleets a significant edge in cost savings over the lifespan of a vehicle. The reduction in fuel usage supports sustainability goals while allowing operators to carry more tools, equipment, and cargo with each trip.

Integrating Advanced Safety Features

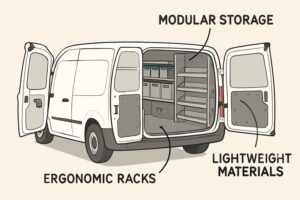

Modern fleet safety is about more than meeting minimum compliance—it’s about proactive risk reduction and fostering safer working environments. Fleet vehicle upfitting now typically features integrated backup cameras, lane departure warnings, and sophisticated collision avoidance systems. These technologies help drivers avoid accidents and lessen liability risks. Beyond electronics, smart ergonomic enhancements such as ergonomic racks, slide-out shelving, and adjustable storage solutions minimize driver strain and reduce injuries caused by repetitive motion or awkward lifting. Paying attention to driver comfort and accessibility serves both the people behind the wheel and the bottom line, resulting in fewer accidents and greater productivity.

Implementing Modular Storage Systems

One of the standout trends in fleet vehicle upfitting is the move toward highly flexible modular storage systems. Unlike permanent fixtures, modular solutions make it easy to adapt a fleet vehicle’s interior for new projects or changing job requirements. Adjustable shelving, customizable tool racks, and partitioned drawers ensure everything has a secure, accessible place. The result is reduced downtime caused by searching for tools, faster project completion, and improved organization—crucial benefits for businesses that rely on quick, precise service responses.

Leveraging Technology Integration

The integration of advanced technology into fleet vehicles does not stop at safety. Fleet management is being revolutionized by onboard telematics, real-time GPS tracking, and smart diagnostics. These systems provide actionable insights into driver behavior, route efficiency, and predictive maintenance needs. With instant data, fleet managers can optimize route planning, forecast potential maintenance issues before breakdowns occur, and ensure drivers adhere to best practices. This data-driven approach helps cut operational costs and enhances accountability across the fleet.

Focusing on Sustainability

Sustainability objectives are shaping fleet upfitting decisions more than ever. Companies are seeking eco-friendly materials, recycled components, and aerodynamic vehicle designs to lower environmental impact. Power solutions such as integrated solar panels are gaining popularity, particularly for mobile workstations that previously relied on gasoline-powered generators for tools and lighting. By embracing these innovations, fleet operators contribute to greener business operations while often benefiting from lower operational costs and extending vehicle service life.

Customizing for Industry-Specific Needs

Every industry brings unique requirements to fleet upfitting projects. For instance, HVAC service vans benefit from custom racks designed to securely store pipes, ducts, and specialized tools, while electrical contractors might need insulated compartments for sensitive instrumentation. Upfitting specialists work closely with these industries to develop tailored storage, access, and protection solutions that directly enhance workforce efficiency and safety. The value of customization lies in its ability to streamline workflows, minimize damage to cargo, and ensure every tool is kept accessible and protected during transport.

Conclusion

Innovative approaches in fleet vehicle upfitting are reshaping the future of commercial transportation. By embracing lightweight materials, integrating advanced safety systems, implementing modular storage, leveraging technology, and committing to sustainable practices, fleet managers can unlock increased efficiency, reduced liability, and superior adaptability. Thoughtful customizations aligned with specific industry demands further amplify these benefits, ensuring that modern fleets are equipped to face tomorrow’s operational challenges with agility and confidence.